Introduction

Images from a DEKRA VT1000 inspection camera is a versatile and high-performance tool designed for a wide range of industrial and environmental inspections. Whether you’re monitoring underwater structures, inspecting pipelines, or assessing hazardous areas, the VT1000’s high-resolution imaging and advanced features make it ideal for challenging inspection tasks.

In this article, we will explore the features, applications, benefits, and practical tips on using the DEKRA VT1000, making it a valuable tool in many industries.

Key Features of the DEKRA VT1000

The DEKRA VT1000 comes with several key features that make it suitable for a variety of inspection scenarios. Below are some of its standout capabilities.

1. High-Resolution Imaging for Clearer Inspections

The DEKRA VT1000 provides HD-quality imaging, allowing users to capture sharp, detailed images even in difficult conditions. This is especially crucial for inspecting intricate parts or identifying small defects in hard-to-reach areas. With high-resolution imaging, you can ensure that you don’t miss any important details during an inspection.

- Resolution: Offers HD-quality images to enhance clarity.

- Image Detail: Captures small and hard-to-spot issues with precision.

2. 30x Optical Zoom for Close-Up Views

With the 30x optical zoom, users can closely inspect components from a distance, enhancing the camera’s ability to detect hidden problems. This feature is essential for inspecting parts that are far away or inside confined spaces.

- Zoom Flexibility: Ideal for detailed inspections from a safe distance.

- Deep Inspections: Perfect for examining inaccessible areas such as deep pipes or tanks.

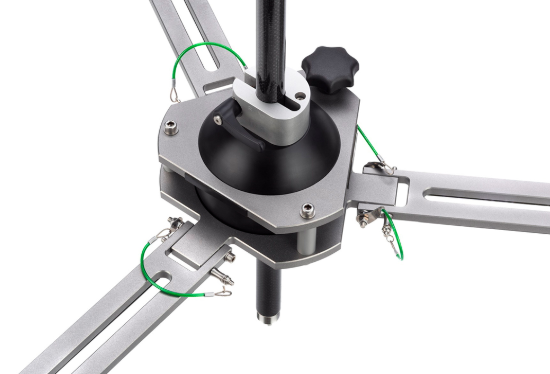

3. Pan and Tilt Function for Wide-Area Coverage

The pan and tilt functionality of the VT1000 allows users to move the camera to various angles, ensuring comprehensive coverage of inspection areas. This feature helps you inspect larger areas without repositioning the camera too often.

- Wide-Area Access: Provides thorough inspection across large areas.

- Efficient Coverage: Avoids the need for repositioning the camera frequently.

4. Integrated Lighting for Enhanced Visibility

The VT1000’s integrated lighting illuminates dark environments, making it easier to inspect objects in low-light or underwater areas. The lighting feature is adjustable, so you can modify the intensity based on your inspection requirements.

- Adjustable Intensity: Lighting can be adjusted based on inspection needs.

- Improved Visibility: Perfect for inspecting spaces with poor lighting conditions.

5. Waterproof Design for Underwater Inspections

The DEKRA VT1000 is engineered to withstand underwater environments, making it ideal for inspecting submerged structures or pipelines. It is built to operate efficiently in environments where other cameras may fail.

- Waterproof Rating: Capable of operating at depths of up to 15 meters underwater.

- Durability: The camera is resistant to corrosion from saltwater.

Applications of the DEKRA VT1000

The DEKRA VT1000 is ideal for a wide range of industrial and environmental inspection tasks. Below, we delve deeper into the various applications across different industries.

1. Oil and Gas Industry

In the oil and gas sector, maintaining the integrity of pipelines, storage tanks, and offshore platforms is critical. The VT1000 is designed to conduct thorough inspections of these essential assets. With its ability to handle harsh environments and detect minute details, it ensures that operators can identify problems before they escalate.

- Pipeline Inspections: The camera’s high-resolution imaging and zoom features enable the inspection of pipelines, both inside and out.

- Rig and Tank Monitoring: Useful for inspecting tanks and offshore oil rigs, ensuring structural integrity.

2. Marine Industry

In the marine industry, the VT1000 is perfect for inspecting ships, underwater structures, and offshore platforms. Whether you need to examine a ship’s hull or submerged infrastructure, the camera provides reliable, detailed imaging.

- Ship Hull Inspections: Inspect hulls for signs of wear, corrosion, or damage.

- Underwater Infrastructure: Assess submerged structures like piers, docks, and underwater pipelines.

3. Chemical and Petrochemical Industries

Chemical plants and refineries need constant monitoring of pipelines, reactors, and storage tanks. The DEKRA VT1000 helps ensure these systems remain safe and functional, reducing the risk of costly failures and accidents.

- Chemical Reactor Monitoring: Inspect reactors for any faults or signs of malfunction.

- Storage Tank Inspections: Regularly check storage tanks for corrosion, leaks, or contamination.

4. Industrial Facilities

From routine maintenance to emergency inspections, the DEKRA VT1000 is invaluable in industrial facilities, allowing for detailed examination of machinery and infrastructure. The camera’s portability and ease of use make it suitable for both scheduled and ad-hoc inspections.

- Factory Equipment: Monitor machinery for damage, wear, or defects.

- Safety Inspections: Ensure safety features are operational and up to code.

DEKRA VT1000 Performance Specifications

Here’s a table summarizing the main performance specifications of the DEKRA VT1000 inspection camera. This quick reference guide helps highlight the camera’s technical capabilities:

|

Specification |

Details |

|

Resolution |

HD 1080p Imaging |

|

Zoom |

30x Optical Zoom |

|

Lighting |

Adjustable LED Lighting |

|

Waterproof Rating |

Up to 15 meters |

|

Pan & Tilt Range |

360° Horizontal, 90° Vertical |

|

Battery Life |

6-8 hours continuous use |

|

Display Type |

7-inch LCD Screen |

|

Weight |

2.5 kg |

| Operating Temperature |

-20°C to 50°C |

Benefits of Using the Images from a DEKRA VT1000

Images from a DEKRA VT1000 offers numerous benefits, making it a smart investment for various industries. From improving safety to increasing operational efficiency, here are some key advantages.

1. Improved Safety During Inspections

The VT1000 reduces the need for personnel to enter hazardous or confined spaces, minimizing the risk associated with inspections. This feature is especially beneficial in industries like oil and gas, where dangerous environments are common.

- Remote Operations: Inspect without physically entering dangerous areas.

- Increased Safety: Minimize exposure to toxic substances, high-pressure zones, or confined spaces.

2. Cost-Effective and Efficient Inspections

By detecting problems early, the VT1000 helps companies save on repair and maintenance costs. The camera ensures inspections are performed quickly and accurately, saving time and money in the long run.

- Preventive Maintenance: Identify issues before they require costly repairs or downtime.

- Reduced Inspection Time: Efficiently cover large areas without the need for repositioning.

3. Versatility Across Different Industries

The DEKRA VT1000 is adaptable, making it useful across various sectors. From marine and oil and gas to industrial and chemical industries, its versatile features ensure that it meets the needs of diverse applications.

- One Tool for Multiple Tasks: Suitable for diverse inspection requirements.

- Industry Flexibility: Works seamlessly across various operational environments, whether submerged or in confined spaces.

How to Use the DEKRA VT1000 Effectively

Here are some tips and best practices for setting up, operating, and maintaining the DEKRA VT1000 to maximize its potential.

1. Setting Up the Camera for Inspection

Before starting, ensure that the VT1000 is properly calibrated and ready for use. Adjust the zoom, lighting, and camera angles to suit your inspection needs.

- Zoom Calibration: Set the zoom to an appropriate level based on the area being inspected.

- Lighting Adjustment: Adjust the lighting intensity depending on whether you’re in a well-lit or dark area.

2. Conducting the Inspection

While performing the inspection, carefully move the camera to cover all critical points of interest. Take high-quality images or videos for later analysis.

- Pan and Tilt Usage: Rotate the camera to get a complete view of the area.

- Image Capture: Capture detailed images of any anomalies or potential issues for further review.

3. Post-Inspection Maintenance

To maintain the camera’s performance, clean it after each use. Regular maintenance is essential to ensure longevity.

- Lens Cleaning: Use a microfiber cloth to wipe down the camera lens.

- Seal Check: Inspect waterproof seals to ensure they are intact, especially after underwater inspections.

Advanced Tips for Using the DEKRA VT1000

To get the best results, here are some advanced tips for optimizing your use of the DEKRA VT1000.

1. Use for Multi-Angle Inspections

Taking advantage of the pan and tilt functionality allows you to inspect areas from multiple angles. This ensures you don’t miss anything important, especially in large or complex structures.

- Multi-Angle Views: Avoid blind spots by inspecting each area from different perspectives.

- Thorough Coverage: Ensure you cover all angles during a single inspection.

2. Combine with Other Tools for Comprehensive Inspection

While the VT1000 is highly capable, pairing it with other diagnostic tools, such as ultrasonic sensors or thermal cameras, can provide a more comprehensive inspection.

- Enhanced Diagnostics: Use additional tools to complement the camera’s capabilities.

- Broader Insight: Gather more data for a detailed understanding of the inspected area.

Conclusion

Images from a DEKRA VT1000 inspection camera is a highly efficient, versatile, and reliable tool designed to meet the demands of modern inspection tasks. With its advanced features, including high-resolution imaging, optical zoom, pan and tilt capabilities, and waterproof design, it stands out as a top choice for various industries, including oil and gas, marine, petrochemical, and industrial sectors.

By utilizing Images from a DEKRA VT1000, companies can enhance safety, streamline inspections, and save costs on repairs and maintenance. Whether you’re working in hazardous environments or inspecting hard-to-reach areas, the VT1000 provides the necessary tools to ensure thorough and effective inspections.

Investing in the DEKRA VT1000 inspection camera ensures that you have a reliable tool to keep your operations running smoothly and safely, minimizing downtime and preventing costly errors.

FAQs About the DEKRA VT1000 Inspection Camera

What is the zoom capability of the DEKRA VT1000?

The DEKRA VT1000 offers a 30x optical zoom for detailed inspections from a distance.

How deep can the DEKRA VT1000 operate underwater?

It can operate at depths of up to 15 meters underwater.

How long does the battery last?

The battery lasts around 6 to 8 hours of continuous use.

Can it be used in hazardous environments?

Yes, the VT1000 is designed for use in harsh, hazardous environments.

Is it beginner-friendly?

Yes, it has intuitive controls, making it easy for beginners to use.

Does it have adjustable lighting?

Yes, it features adjustable LED lighting for optimal visibility.